Corgan Create: Expanechoic Seating

When Corgan Create kicked off in 2014, it was a natural extension of the firm’s spirit of agility and innovation. Supporting the curiosity of individuals who want to explore emerging technologies, design methodologies, or any “big idea” they are passionate about has led to an array of projects with real design applications. That even off-duty Corgan employees favor human-centric, user-experience focused projects isn’t surprising, but it is rewarding to see the genuine passion for Corgan’s ethos beyond the job description.

Just as in years past, the 2023 finalists showcased their innovation, determination, and imagination during the first Create event back since the pandemic. Here is one of the three finalists:

Expanechoic Seating

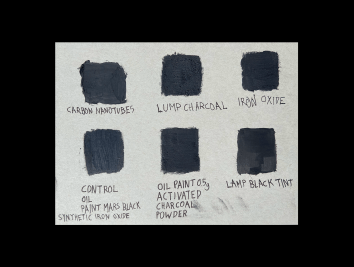

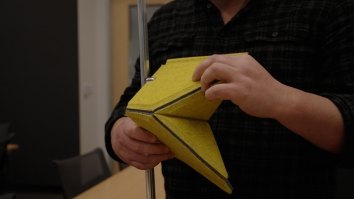

To fill a gap he saw in the furniture currently available for in-office collaboration spaces, Gabriel Oros developed a modular, adaptable version of campfire seating that he has dubbed Expanechoic Seating. The name – a portmanteau of “expanding” and “anechoic” – refers to both the physical flexibility of the piece and the acoustic sheltering it provides to users. He wanted to improve upon a paper version of the seat that is very fluid, but not durable for casual public use. To combat lateral forces, his first prototype used bamboo plywood as the main structural material. While adding connection points would reduce the lateral movement, it would remove the flexibility Gabriel was aiming for. He added hinges but wasn’t happy with the way the segments pivoted like a bike chain – he wanted them to fan out like a Slinky. The answer to this problem turned out to be spring-loaded hinges that provided a sleek look. With “expan-” taken care of, Gabriel turned to the “-anechoic” portion of his project: what material would look good, be acoustically isolating, and move with the seating? To further enforce the sustainable aspect of this piece, he found his material – PET fabric made from 100 percent recycled plastic water bottles – and experimented with folding panels inspired by “Miura” paper folding. He ultimately landed on a sliding bearing connection to better embrace the inherent movement of the unit. Finally, after many iterations, he landed on a combination that did what he had set out to do.

Q&A

What was the spark? What made you think “I should see what would happen if…”?

Following the pandemic, there was a surge in people returning to the office. The influx of staff mixed with a large number of summer interns and resulted in our office being at max capacity. Due to the high number of staff in the office, our collaboration spaces were either disrupting the desks nearby, or noise was interfering with the group that had gathered. Conference room availability was at a premium and we were just simply running out of spaces. My thought after all of this was “is there a way to introduce some kind of furniture element that could create acoustic isolation, but also adapt to an open-office environment without the need of constructing a permanent conference room?”.

How did you simplify your “big idea” into a doable project? Were there any difficulties?

Conceptually everything seemed pretty simple. Its initial intent was to be a scalable piece made up of a kit of parts that would just be replicated. The R&D portion was challenging, but exciting! Each component would present a problem or obstacle, but working through the issue created a new step in the innovation aspect to it. The largest difficulty I faced was some of the material limitations presented by the acoustic component of the design. However - fortunately - that has moved into a next step of development with a partnering manufacturer.

What is/was the vision, ideally?

The ideal vision is a flexible, scalable, modular seating element that would provide a visual and acoustic barrier for an open office environment. The entire piece was intended to be made from recycled and environmentally friendly material. Knowing this would be deployed in an open office environment, the hope was to make something visually pleasing with no “back-side.” The acoustic component would create a new typology lending to flexible acoustic design solutions.

What is the next step, practically?

In the short-term, the next step is to continue developing the acoustic portion of the project. I have been in contact with manufacturers who are interested in teaming up with Corgan to help develop this portion of the project. Long-term, the next step (once the acoustic portion is figured out) would be to partner with a furniture manufacturer to distribute this design at a larger production scale. Due to the sustainability aspect of it, and multi-color opportunities, there is an endless list of application opportunities the use this design.

How will you know when the project is successful?

The mark of success will be how much it continues to be used as a gathering space and how long there is continued enthusiasm for its development. Manufacturers have shown early excitement in how this project proceeds so hopefully the momentum continues.